THE THINGS WE ARE ABLE TO DO

China auto mechanic tools manufacturers and auto mechanic tools suppliers

Air Tools

Tire Valves

Wheel Nuts & Spacers

Work Shop Equipments

Tire Patch

Wheel Weights

Work Shop Tools

TIRE VALVES & ACCESSORIES

-

WHEEL WEIGHTS

When the vehicle is running at high speed, the wheels move up and down during the vibration process, and the wheel weight between the wheel sets will increase or decrease. The deviation of the wheel weight is caused by the small (or no) lateral force, and it may also be caused by lateral relative displacement with the wheel Derailment occurred.View Detall -

TIRE REPAIR MATERIALS

Internal patch tire repair: more robust, but not once and for all. In addition, the tire will generally be dynamically balanced after repair, which is more conducive to the use of the tire.View Detall

Mushroom tyre repair: Because the damaged part is completely blocked, it prevents water from immersing from the damaged place and damaging the tire steel wire and ply. Therefore, it is a safer and more reliable tire repair method. -

AIR TOOLS

Pneumatic wrenches, jackhammers, pneumatic ratchet wrenches, pneumatic perforation wrenches, pneumatic nail guns, pneumatic cap pullers, pneumatic rivet guns, pneumatic drills.View Detall -

WORK SHOP TOOLS

Tool wall cabinets, side cabinets, beautiful appearance; high-quality shelves, drawers, heavy-bearing, drawers can be separated as needed; space saving, strong applicability.View Detall -

WHEEL NUTS & SPACERS

The biggest advantage of this nut is that there is a cap on the back of the nut, which can protect the exposed thread of the bolt from being damaged by external forces.View Detall -

WORK SHOP EQUIPMENTS

The workbench is made of high-quality cold-rolled board, and the firm work table frame is firm and stable, which can make the work table load 1000kg; a variety of work table options can meet the requirements of non-working use; the tool wall cabinet has a beautiful appearance; The drawers are of high quality and load-bearing. The inside of the drawers can be separated as needed; it saves space and has strong applicability.View Detall

-

How to prevent valve stem damage when installing or removing inner tubes?

Preventing valve stem damage during the installation or removal of inner tubes requires care and attention to detail. Here are some steps you can take: Use Proper Tools: Select tire levers that match ...

Read More -

How to correctly inflate inner tubes with different types of valves to ensure positive performance and safety?

Inflating inner tubes with different valve types requires specific techniques to ensure positive performance and safety: Identify Valve Type: Start by visually inspecting the valve on your inner tube....

Read More -

How does the trigger control on this air impact wrench affect precision and ease of use?

The trigger control on an air impact wrench plays a crucial role in both precision and ease of use: Precision: The trigger control of an air impact wrench serves as the primary interface between the u...

Read More -

Pb Wheel Weights: A Critical Component in Automotive Safety

Pb Wheel Weights play a crucial role in ensuring automotive safety by contributing to the overall balance and stability of vehicles. These small yet significant components are strategically attached t...

Read More -

Engineered for Strength: Engine Crane (Folding Type) Tackles Tough Jobs

When it comes to heavy lifting in workshops or industrial settings, having equipment that can handle the challenge is paramount. This is where the Engine Crane (Folding Type) shines. With its robust c...

Read More -

The Mechanics of Fastening: How Wheel Bolts Secure Tires to Vehicles

The mechanics of fastening, particularly in the context of wheel bolts securing tires to vehicles, represents a crucial aspect of automotive engineering that often goes unnoticed by many drivers. At i...

Read More -

Efficient Elevation: Engine Crane (Folding Type) Raises Engines with Precision

When it comes to the intricate task of raising engines for maintenance or repair, precision and efficiency are paramount. Engine Crane (Folding Type) stands as a testament to modern engineering ingenu...

Read More -

Innovations in Wheel Bolt Technology: Advancing Automotive Safety

In the ever-evolving landscape of automotive engineering, even the smallest components play a pivotal role in enhancing vehicle safety and performance. Among these components, wheel bolts have seen si...

Read More -

The Inner Workings of Tpms Valves: Ensuring Tire Safety

Tpms Valves are a crucial component in modern vehicles, playing a vital role in ensuring tire safety and overall driving performance. These valves are part of a sophisticated system designed to monito...

Read More -

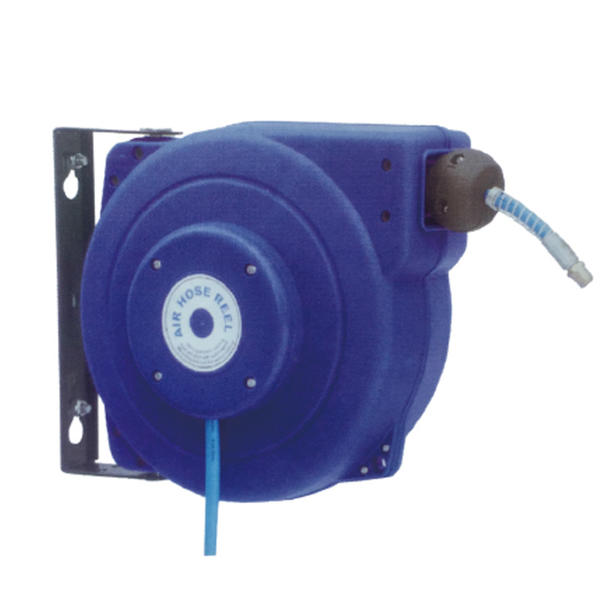

Exploring the internal structure of air hoses: a key design for enhanced pressure resistance

The internal structure of an air hose is a crucial part of its design, which directly affects the pressure resistance, flexibility and service life of the hose. Generally speaking, the internal struct...

Read More -

Exploring the Air Compressor: Precision Engineering from Compressed Air to Driving Power

An air compressor is a mechanical device whose function is to compress the air in the environment to increase its pressure to a higher level. This process reduces the distance between air molecules, c...

Read More -

Tire valve: the important mission of a small thing

Tire valves, as a small but critical component of a vehicle, play an integral role in vehicle performance and driving safety. Although it looks like just a small valve, it carries important functions ...

Read More

English

English Español

Español Deutsch

Deutsch Français

Français